February 11, 2026

February 11, 2026

في عالم الكوكتيلات الحرفية وتناول الطعام الفاخر، تبدأ الرحلة من كتلة جليدية صافية لنحتها بشكل مثالي كرة ثلج صالحة للأكل يمثل فنًا وعلمًا في آنٍ واحد. في حين أن معظم المستهلكين يدركون الجاذبية البصرية لـ جليد صافي كالكريستال في مشروباتهم، قليلون هم من يدركون العمليات المعقدة التي تُحوّل الماء المتجمد العادي إلى هذه التكوينات النقية. وقد أدى الطلب المتزايد على الثلج الشفاف في البيئات التجارية والسكنية إلى تطورات كبيرة في تكنولوجيا الجليد الصافيمما جعل ما كان متاحًا حصريًا للمؤسسات الراقية متاحًا لسوق أوسع. يستكشف هذا المقال عملية التحول الرائعة، والمبادئ التقنية، والتطبيقات العملية وراء إنشاء كرات جليدية مثالية باستخدام جهاز متخصص. آلة صنع مكعبات الثلج التي تصنع كرات الثلج وغيرها من المعدات.

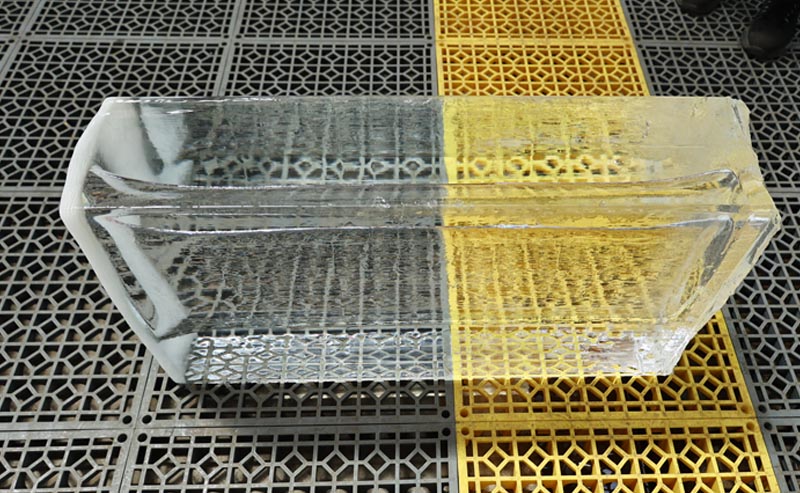

تبدو مكعبات الثلج التقليدية غائمة وبيضاء اللون بسبب فقاعات الهواء المحبوسة والمعادن والشوائب التي تتراكم أثناء عملية التجميد. عندما يتجمد الماء من الخارج إلى الداخل، تُدفع هذه العناصر نحو المركز، مما يُنتج ذلك اللب المعتم المميز. جليد صافي كالكريستالعلى النقيض من ذلك، يتشكل التجمد من خلال التجميد الاتجاهي المتحكم فيه والذي يسمح للشوائب والفقاعات الهوائية بالهروب قبل التصلب الكامل.

آلة صنع مكعبات الثلج الشفافة التجارية تستخدم الوحدات أنظمة متطورة لتحقيق هذا الوضوح. تتميز هذه الآلات عادةً بألواح تبريد في الأسفل وأنظمة تدوير مياه تُشجّع على التجميد الاتجاهي من الأسفل إلى الأعلى. تُتيح هذه الطريقة للهواء المحبوس والمعادن المذابة مسارًا للهروب إلى الماء غير المتجمد المتبقي، والذي يُتخلص منه لاحقًا. والنتيجة هي... كتلة ثلج شفافة خالية من العيوب التي توجد في مكعبات الثلج القياسية.

يكمن سر إنتاج ثلج نقي في التحكم في اتجاه وسرعة التجميد. عندما يتجمد الماء في اتجاه واحد، فإنه يُشكل بلورات أكبر وأكثر تنظيمًا، مما يُقلل من فقاعات الهواء. هذا المبدأ العلمي هو أساس جميع الممارسات المهنية. تكنولوجيا الجليد الصافيمن الآلات التجارية إلى أساليب الصيانة المنزلية.

آلة صنع الثلج الشفاف الصناعية تُطبّق النماذج ذلك من خلال أنظمة درجة حرارة مُعايرة بدقة. من خلال الحفاظ على درجات حرارة تجميد مثالية (عادةً ما بين -8 و-4 درجات مئوية) والتحكم في معدل التبلور، تُنتج هذه الآلات نتائج واضحة باستمرار. تستغرق العملية عادةً من 24 إلى 72 ساعة، حسب حجم الكتلة ومواصفات الآلة، وهي مدة أطول بكثير من إنتاج الثلج التقليدي، ولكنها تُعطي جودة أعلى بكثير.

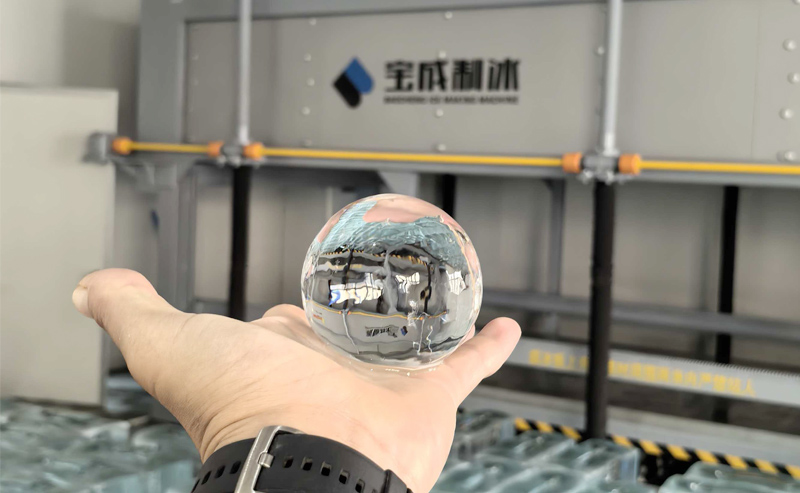

قبل التخصص معدات آلة صنع كرات الثلج مع انتشارها على نطاق واسع، اعتمد الحرفيون على الطرق اليدوية لصنع كرات الجليد. تبدأ هذه العملية بكتلة جليدية شفافة كبيرة تُحصد من آلة صنع مكعبات الثلج الشفافة التجاريةثم يستخدم الحرفيون مجموعة من الأدوات اليدوية - بما في ذلك معاول الثلج والسكاكين والمناشير المتخصصة - لنحت الكتلة تدريجيًا إلى شكل كرة.

تتبع العملية اليدوية عادةً الخطوات التالية:

مع أن هذه الطريقة توفر تحكمًا فنيًا كاملاً وتتطلب معدات بسيطة، إلا أنها تتطلب مهارة ووقتًا وممارسة كبيرة لإتقانها. إضافةً إلى ذلك، يُنتج النحت اليدوي هدرًا كبيرًا، إذ يُزال عادةً أكثر من نصف كتلة الجليد الأصلية أثناء عملية التشكيل.

تعتمد العمليات التجارية الحديثة بشكل متزايد على آلات متخصصة لتحويل كتل الجليد الشفافة إلى كرات مثالية بكفاءة أكبر. وتشمل هذه الطرق الميكانيكية ما يلي:

يبدأ أساس ثلج كريستالي نقيّ تمامًا بماء مُحضّر جيدًا. مع أن التجميد الموجّه يُعوّض عن بعض الشوائب، إلا أن جودة الماء تُؤثّر بشكل كبير على النقاء النهائي. يستخدم المحترفون عادةً:

تنتج معالجات المياه المختلفة نتائج مختلفة، أنظمة آلات صنع الثلج الشفاف التجارية غالبًا ما تتضمن أنظمة ترشيح وإزالة الهواء مدمجة لتحسين مصدر المياه تلقائيًا.

إن إدارة درجة الحرارة بشكل ثابت طوال عملية التجميد أمر بالغ الأهمية لنقاء الجليد. آلة صنع مكعبات الثلج الصناعية الشفافة تحافظ الوحدات على تحكم دقيق في درجة الحرارة لضمان تكوين بلورات مثالي. تشمل الاعتبارات الرئيسية ما يلي:

وتستخدم الأنظمة المتقدمة حاويات معزولة وعناصر تبريد معايرة بدقة للحفاظ على هذه الظروف المثالية طوال عملية التجميد التي تستغرق عدة أيام.

يؤثر الاختيار بين أنواع مختلفة من تقنيات الثلج الشفاف بشكل كبير على قدرة الإنتاج، واتساقه، وتعقيد العمليات. يجب على العمليات التجارية مراعاة ما يلي:

احترافي آلة صنع مكعبات الثلج الشفافة تتراوح الوحدات من 5000 دولار إلى 10000 دولار أنظمة إنتاج كتل الثلجمع الحاجة إلى استثمار إضافي لمعدات النحت أو التشكيل. وتظل الصيانة الدورية، بما في ذلك تنظيف الرواسب المعدنية وضمان مستويات التبريد المناسبة، ضرورية لضمان أداء ثابت.

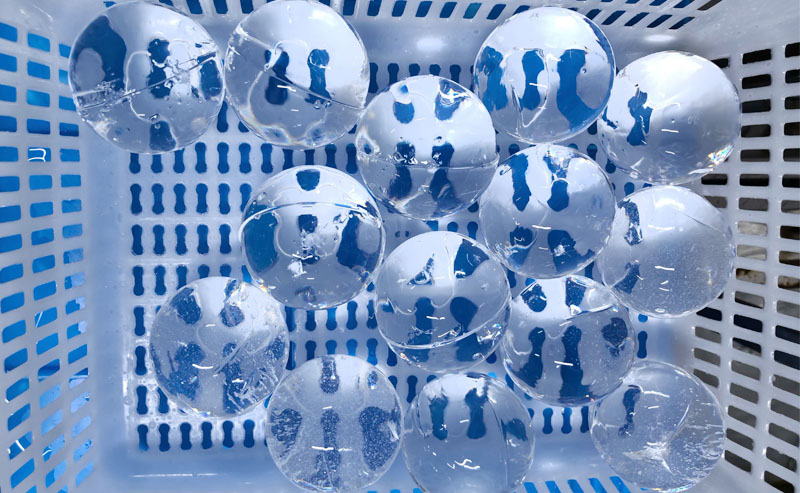

أدى انتشار صناعة الكوكتيلات الحرفية إلى انتشار استخدام كرات الثلج الشفافة في الحانات والمطاعم الراقية. وتشمل تطبيقاتها:

يمكن للمؤسسات تشغيل أنظمة آلة صنع الثلج الشفاف الخاصة بها أو الحصول عليها من موردين متخصصين يقومون بإنتاج وتسليم كرات الثلج الشفافة.

بالإضافة إلى المشروبات، فإن الثلج الشفاف له تطبيقات في:

إن التأثير البصري للجليد الصافي تمامًا يجعله شائعًا لـ:

يعاني العديد من المشغّلين من عدم ثبات نتائج إنتاج الثلج النقي. تشمل الحلول الشائعة ما يلي:

تشتمل أنظمة آلة صنع مكعبات الثلج التجارية عادةً على مضخات دوران للحفاظ على حركة الماء أثناء التجميد، ومنع البقع الغائمة وضمان الوضوح المستمر في جميع أنحاء الكتلة.

يُشكّل وقت التجميد المُطوّل اللازم لتحقيق أقصى قدر من الوضوح تحديات تشغيلية، خاصةً للمؤسسات ذات الحجم الكبير. تشمل استراتيجيات معالجة هذا الأمر ما يلي:

ركزت التطورات الأخيرة في تكنولوجيا الثلج الشفاف على تقليل وقت الإنتاج مع الحفاظ على الجودة، حيث حققت بعض الأنظمة الأحدث درجة وضوح مقبولة في أقل من 24 ساعة.

تتطلب معدات إنتاج الثلج التجارية مساحةً ماديةً كبيرةً ودعمًا للبنية التحتية. قد تأخذ العمليات ذات المساحة المحدودة في الاعتبار ما يلي:

يمثل تحويل كتلة ثلج صافية إلى كرة ثلجية صالحة للأكل تقاطعًا متطورًا بين الهندسة الدقيقة والحرفية الفنية. بفضل التجميد الاتجاهي المُتحكم به، والمعدات المتخصصة، وتقنيات المعالجة الدقيقة، يمكن للعمليات التجارية إنتاج ثلج نقي كالكريستال، يُضفي لمسةً من النقاء على تجارب المشروبات والعروض الطهوية.

مع التطور المستمر لتكنولوجيا الثلج الشفاف، أصبحت هذه العمليات متاحة بشكل متزايد للمؤسسات بمختلف أحجامها. يوفر السوق الآن حلولاً تتراوح من أنظمة آلات صنع مكعبات الثلج الشفاف الصناعية التي تنتج مئات الكتل أسبوعيًا، إلى وحدات سطح العمل المدمجة المصممة للعمليات الصغيرة.

سواء كنت متخصصًا في الضيافة وتسعى إلى تحسين برنامج المشروبات الخاص بك أو مالك عمل يستكشف إنتاج الثلج عالي الجودة، فإن فهم هذه المبادئ والعمليات الأساسية يوفر الأساس للتنفيذ الناجح.

هل أنت مستعد لرفع مستوى مؤسستك باستخدام كرات الثلج الشفافة؟ اتصل بفريقنا المتخصص للحصول على توصيات مخصصة بالمعدات ودعم التنفيذ التجاري. استكشف مجموعتنا من حلول آلات صنع الثلج الشفاف الاحترافية، المصممة لتناسب جميع أحجام العمليات.

جهات الاتصال الخاصة بنا

البريد الإلكتروني: sales@baocharm.com

واتساب: +86 17663537579

وي شات: +86 17663537579

ساعات العمل: من الإثنين إلى السبت من الساعة 8:30 صباحًا حتى 5:30 مساءً